Systematic troubleshooting process for leakage issues

Establishing a standardized investigation process can quickly locate the source of leaks. Firstly, confirm the specific location and type of medium where the leak occurred, and then gradually inspect each connecting part. Use appropriate testing tools, such as leak detectors or gas detectors, to accurately identify the leak point. Analyze the working pressure and temperature of the leaked medium to determine if it exceeds the rated parameters of the solenoid valve. Record the frequency and pattern of leaks to provide a basis for preventive maintenance.

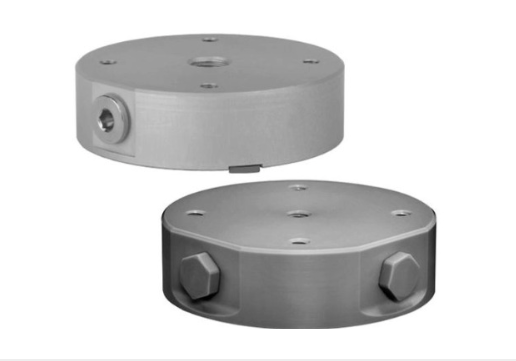

Inspection and replacement standards for key components

Sealing components are the core components that prevent leakage. Regularly check the hardness changes and surface condition of the seals, and replace them immediately if permanent deformation or cracks are found. The valve core component needs to be checked for its flexibility and surface smoothness, as any jamming or wear may result in poor sealing. When replacing components, it is necessary to ensure that the new parts are completely consistent with the original specifications, and clean all contact surfaces before installation to avoid impurities affecting the sealing effect.