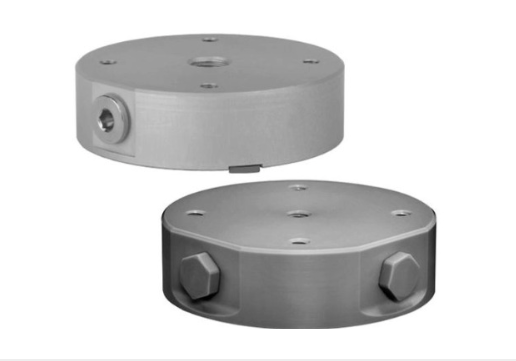

Pre-installation preparation Before installation

carefully check whether the cylinder model matches the installation accessories, and confirm the flatness and cleanliness of the installation base. Prepare the necessary tools and fasteners to ensure a smooth installation process.

Key points of installation process

During installation, extra stress should be avoided on the cylinder to ensure that the piston rod remains concentric with the load connection. When tightening bolts, a diagonal alternating method should be used to gradually reach the specified torque value in stages.

Check after installation

After installation, it is necessary to check whether the cylinder moves smoothly and whether there is any jamming phenomenon. Conduct a no-load test to confirm that all connection parts are firm and reliable, with no signs of looseness